Technical Specifications

- Detection limits:

- H2S/TOS TS MEDOR® ppb: 5 ppb H2S (7 μg/m3)

- H2S/TOS TS MEDOR® ppm: 0.1 ppm H2S (0.1417 mg/m3)

- Detection range: H2S / TOS / TS

- 0/10, 0/100 or 0/1000 (ppb or ppm)

- Low % with HC sampling valve

- Relative Standard Deviation:

- RSD < 3% on concentration over 48H.

- RSD < 0.6% on retention time over 48H.

- Results:

- Hardware storage

- MODBUS communication protocol (optional)

- 4-20mA (optional)

- Linearity:

- 0.995 for all compounds

- Cycle time:

- H2S / TS result in 2 min for 0-3 ppm range

- H2S / TS result in 5 min for higher range

- Gas supply:

- Carrier: Dry air or N2 (3 bars): 5 ml/min.

- CALIB: in continuous 50 ml/min. (option)

- CALIB during validation ~ 250ml/min (option)

- Pneumatic valve 90ml/commutation

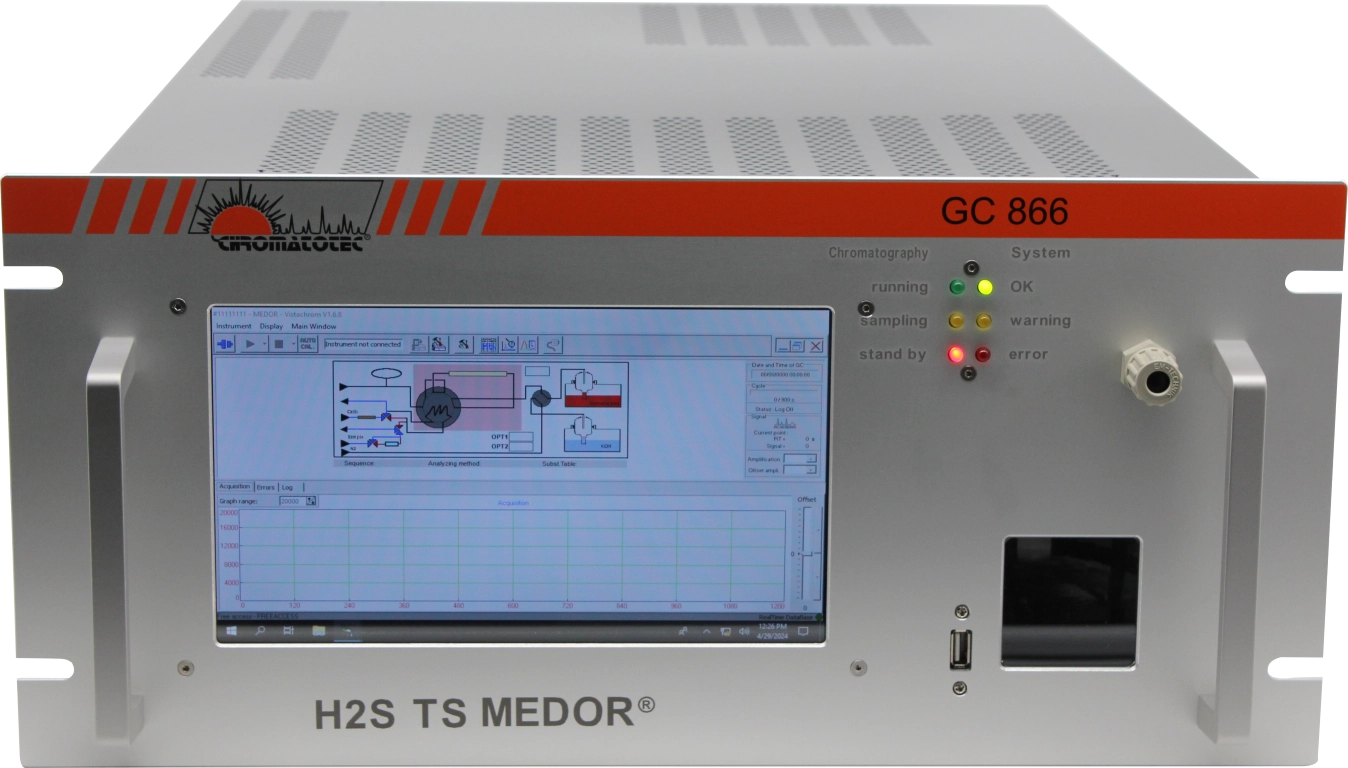

H2S, total organic sulfur and total sulfur

The H2S/TOS TS MEDOR® is an autoGC-ED (MEDOR® Electrochemical wet cell Detector) for the analysis and monitoring of H2S, TOS and TS.

- Different configurations exist depending on the application and concentration range : HS2/TOS TS MEDOR ppb for 0-1 ppm and H2S/TOS TS MEDOR ppm for 0-10 / 0-50 / 0-100 ppm

Principle

- Automatic sampling using a loop

- Automatic loop injection on metallic capillary column

- Isothermal gas chromatograph

- Detection of all compounds eluting from the column performed by MEDOR® detector : Electrochemical wet cell Detector which is a Sulfur Specific Detector (SSD)

- Signal provided by electrochemical reaction between the wet cell electrolyte and the sulfur compounds

- Fully compliant with ASTM D 7493-14 : Standard Test Method for On-line Measurement of Sulfur Compounds in Natural Gas and Gaseous Fuels by Gas Chromatograph and Electrochemical Detection.

- Compliant with ASTM D 5504-20 : Standard Test Method for Determination of Sulfur Compounds in Natural Gas and Gaseous Fuels by Gas Chromatography and Chemiluminescence with alternative detector.

Key points

- Continuous monitoring with automatic online sampling

- Analytical performances :

– Specific, linear and very sensitive to sulfur compounds

– Results validation by automatic standard injection

– Long term stability using detector installed in reservoir - Extremely low maintenance :

– Very long life time detector with electrolyte, up to 10 years.

– Low gas consumption, can be reduced in option

– More than 10 years data storage

– No cylinders required thanks to internal calibration tube and gas generators - Automatic control with process device

- Intelligents system with tunable and interactive alarm levels

- Powerful VISTACHROM Chromatotec® software :

– Remote monitoring & injection control

– Full traceability with on board archiving of results and chromatograms